Floating Ball Valve

FLOATING BALL VALVE

General Information

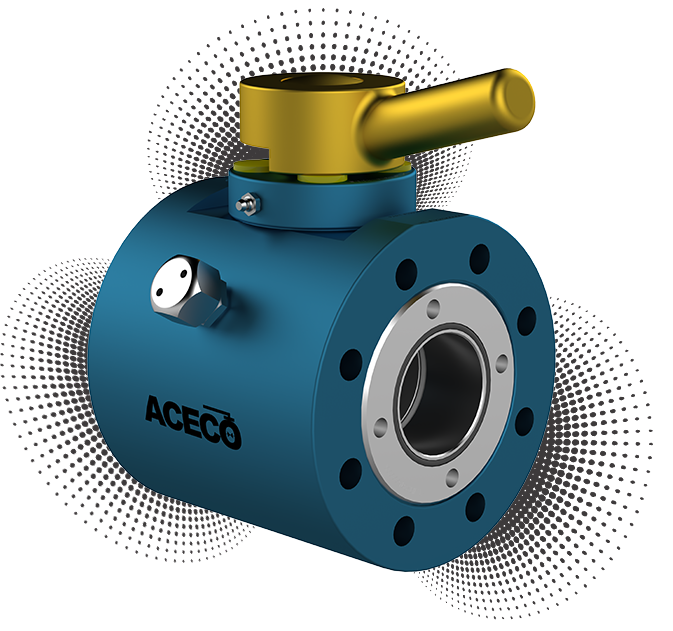

The Aceco Model BV1 compact floating ball valve provides advanced design, high-quality material and superior craftsmanship for cost-effective operation and durability. Aceco has designed the Model BV1 to be a rugged and reliable valve with standard compact end-to-end dimensions and bolt pattern, requiring minimal line spread to facilitate easy removal and replacement.

Share on Social Media

Floating Ball Valve Design and Performance

When it comes to Floating Ball Valve design and performance, Aceco Valves stands out as a reliable and innovative leader in the industry. Our Floating Ball Valves are meticulously crafted to deliver exceptional performance and durability, making them ideal for a wide range of applications.

One of the key features of our Floating Ball Valve design is its simplicity yet effectiveness. The ball in the valve is allowed to float freely between the seats, which ensures a tight seal when closed and reduces the risk of leakage. This design also minimizes the operating torque required, resulting in smooth and efficient valve operation.

At Aceco Valves, we prioritize quality and reliability in every aspect of our Floating Ball Valves. We use high-grade materials such as stainless steel, carbon steel, and exotic alloys to ensure corrosion resistance and longevity even in demanding environments. Our valves undergo rigorous testing and inspection processes to guarantee they meet international standards for safety and performance.

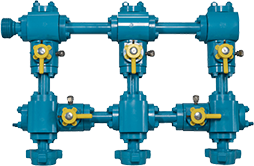

In terms of performance, our Floating Ball Valves offer excellent flow control and are suitable for handling various fluids, including corrosive and abrasive media. They provide reliable shut-off capabilities, making them essential components in industries such as oil and gas, petrochemical, water treatment, and more.

Detailed Specs

Standard Design Key Features

Sizes 1”- 3”

Working Pressures up to 15,000 PSI

Designed to API 6A & API 6D

API 6FA, Fire tested & Certified

NACE MR0175-Latest Edition*

Robust design for ease of operation and durability

Body, Bonnet and End connections are constructed of Carbon, Alloy or Stainless steel

End connections are designed to be welded directly into the line with no other fittings required

Metal-to-metal face seal at the body connection with secondary O-ring seal

Stub Acme Threaded seat retainer:

- additional safety feature eliminates the potential for blowouts

- enables the valve to be installed in either direction

Integral stem lubrication fitting and channel

- minimizes stem/bonnet corrosion

- eliminates stem freeze-ups

Optional Design Feature

Metal Seated

Throttling

Lip Seal

Internal/External Coatings

Locking Device

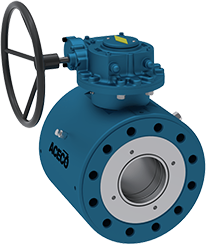

Complete Automated Packages

Why Buy Floating Ball Valve From Aceco Valves?

What sets Aceco Valves apart is our commitment to continuous improvement and innovation. We constantly research and develop new technologies to enhance the performance and efficiency of our Floating Ball Valves, keeping pace with industry advancements and customer requirements.

When you choose Aceco Valves for your Floating Ball Valve needs, you can trust that you’re getting a product that excels in design, performance, and reliability, backed by our expertise and dedication to customer satisfaction.

- Innovative Design: Our Floating Ball Valves feature a meticulously engineered design that prioritizes efficiency, reliability, and ease of operation. The floating ball design ensures a tight seal, reducing the risk of leakage and enhancing overall performance.

- High-Quality Materials: Aceco Valves use only the highest quality materials such as stainless steel, carbon steel, and exotic alloys in the construction of our Floating Ball Valves. This ensures excellent corrosion resistance, durability, and longevity even in harsh operating environments.

- Exceptional Performance: Our Floating Ball Valves are known for their outstanding performance in terms of flow control, shut-off capabilities, and handling a wide range of fluids including corrosive and abrasive media. They are designed to meet stringent industry standards and provide reliable operation under varying conditions.

- Rigorous Testing and Quality Assurance: We subject all our Floating Ball Valves to rigorous testing and quality assurance processes to ensure they meet or exceed industry standards for performance, safety, and reliability. This commitment to quality gives you peace of mind knowing that you’re investing in a high-quality product.

- Industry Experience: With years of experience serving diverse industries such as oil and gas, petrochemical, water treatment, and more, Aceco Valves has gained a reputation for delivering top-notch Floating Ball Valves that consistently exceed customer expectations.