Double Ball Valves

DOUBLE BALL VALVES

General Information

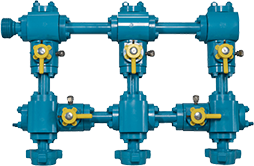

The Aceco Model BV1 and BV2 ball valves are available in Double Ball Designs. This option provides the unique advantage of two valves contained in one solid body eliminating a possible leak path, reducing the amount of end connections required as well as provide for maximum space and weight savings. The double ball valve design provides double isolation as well as true double block and bleed capabilities for safety and seat integrity checks allowing for peace of mind. This is accomplished through the two physical barriers to retain pressure while working downstream of the closed valve.

Share on Social Media

Double Ball Valve Design and Performance

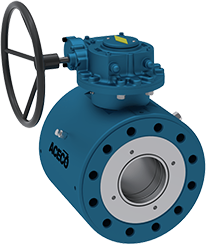

Double Ball Valves are a crucial component in many industries, offering enhanced control and reliability in fluid handling systems. At Aceco Valves, we take pride in our advanced Double Ball Valve designs that ensure optimal performance and efficiency. Our Double Ball Valves feature a unique design with two separate balls and seats, providing a reliable shut-off function even in high-pressure applications. This design minimizes the risk of leakage and ensures a tight seal, contributing to system safety and efficiency.

The materials used in our Double Ball Valves, including stainless steel, carbon steel, and exotic alloys, are of the highest quality to ensure durability and corrosion resistance. This makes our valves suitable for a wide range of industries, including oil and gas, petrochemical, water treatment, and more. Aceco Valves’ Double Ball Valves are designed for smooth operation and low maintenance requirements. They offer excellent flow control capabilities and are suitable for handling various fluids, including corrosive and abrasive media.

Detailed Specs

Standard Design Key Features

Sizes 1”- 3” Floating and 2”-12” Trunnion

Working Pressures up to 15,000 PSI

Robust end connections allow for limited bending loads fully compliant with ASME B31.3

Valve bore sizes are chosen to closely match the most popular pipe bores, minimizing flow turbulence in the valve bore

NACE MR0175-Latest Edition

Minimal line spread for ease of repairability or replacement

Stub Acme Threaded seat retainer:

- additional safety feature eliminates the potential for blowouts

- enables the valve to be installed in either direction

Integral stem lubrication fitting and channel

- minimizes stem/bonnet corrosion

- eliminates stem freeze-ups

The center bleed port between the balls permits seat integrity before conducting any maintenance work downstream of the valve.

Trunnion design allows Double Isolation and Bleed contained in one valve

Why Buy Double Ball Valve From Aceco Valves?

Choosing a Double Ball Valve from Aceco Valves offers numerous benefits and advantages that make us the preferred choice for your fluid handling needs:

- Advanced Design: Our Double Ball Valves feature a unique design with two separate balls and seats, ensuring a reliable shut-off function and minimizing the risk of leakage. This advanced design contributes to system safety and efficiency.

- High-Quality Materials: Aceco Valves uses top-quality materials such as stainless steel, carbon steel, and exotic alloys in the construction of Double Ball Valves. These materials ensure durability, corrosion resistance, and longevity, making our valves suitable for a wide range of industries and applications.

- Enhanced Performance: Our Double Ball Valves are designed for smooth operation and low maintenance requirements. They offer excellent flow control capabilities and can handle various fluids, including corrosive and abrasive media, with ease.

- Customization Options: We offer customization options for Double Ball Valves, including different sizes, pressure ratings, end connections, and materials. This allows us to tailor valves to your specific project requirements, ensuring they fit seamlessly into your system.

- Rigorous Testing and Quality Assurance: All Aceco Valves’ Double Ball Valves undergo rigorous testing and quality assurance processes to ensure they meet or exceed industry standards for performance, reliability, and safety. This commitment to quality gives you peace of mind knowing that you’re investing in a reliable and durable product.

- Technical Support: Our team of experienced engineers and technical experts provides comprehensive support throughout the valve selection, installation, and maintenance process. We are dedicated to assisting our customers in achieving optimal valve performance and operational efficiency.